With more foodservice businesses becoming larger in scale, especially with the growth of central kitchens and more standardized food preparation procedures, cook-chill is becoming increasingly popular. As the name suggests, it is a process of cooking food in quantity, then rapidly chilling it.

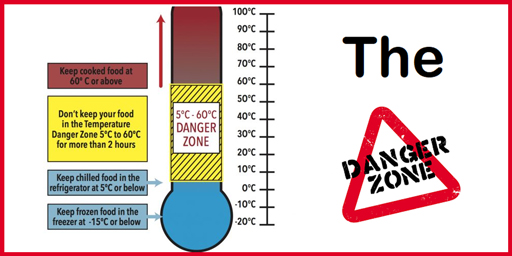

The cooked food is not frozen, but cooled rapidly so that it does not stay in the “danger zone” long enough to support harmful bacteria growth. The “danger” zone is defined by the temperature between 5°C to 57°C, which is the equivalent of 41°F to 135°F.

When it comes to the portioning of foods, it must be done within 30 minutes of cooking so the food can be safely chilled. It is recommended to take regular measurements of the food temperature during this time, and throughout the cook-chill process.

Once it’s been quickly chilled, the food is refrigerated at 1°C to 4°C (34°F to 40°F) to prolong its shelf life, allowing it to sit for at least five days and, sometimes up to 21 days before serving. It should be noted that this can be a method to stockpile leftovers, but it is primarily used to create a stock of safely prepared and refrigerated foods that can be used as needed.

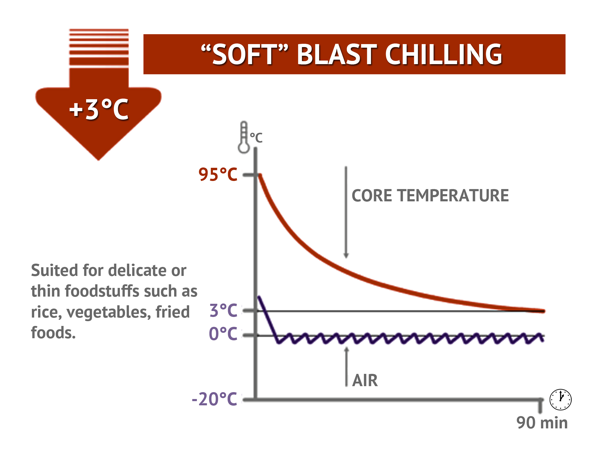

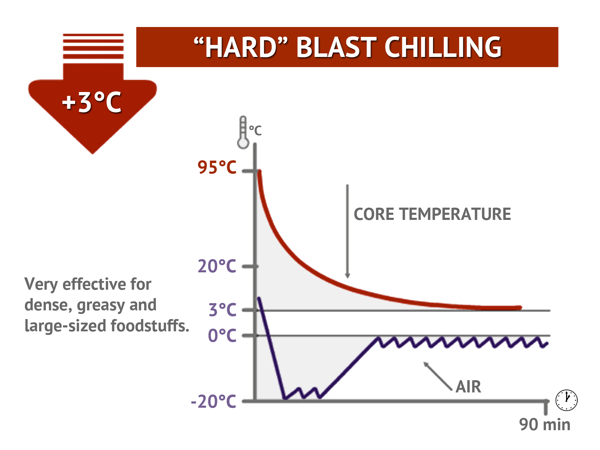

There are two types of quick-chilling, namely blast chilling and tumble chilling. Of the two, the former which circulates cold air at high velocity, is by far the more popular. The other is tumble chilling, which immerses packed food products in cold liquid and is less widely available.

Blast chilling

Ideal for chilling solid foods such as chicken parts, beef rounds, whole casseroles, burger patties, and so forth.

The blast chiller is more sophisticated than a walk-in. It works by blasting the food with cold air at speeds of up to 1300 feet per minute to quickly draw off the heat, thanks to powerful fans.

It also contains an accurate temperature display and built-in food probes with digital displays as well as a timer that will alert kitchen personnel with an audible buzz or bell when it’s done. Most blast chillers come with a holding mode that starts up automatically when blast chilling is complete.

As you might imagine, these units require plenty of power. A typical 10- to 12-trays chiller has a 1- to 2-horsepower motor.

Tumble chilling

Less versatile than blast chillers, but perfect for cooling down liquids such as soups, stews, gravies and sauces as well as some types of pasta

When it comes to reducing food temperatures quickly, the tumble chiller is much more efficient than the blast chiller. Some even go so far as to say that tumble chilling doubles the safe shelf life of foods compared to blast chilling.

Many tumble-chilled foods can be stored safely for 35 to 45 days before rethermalization.

Advantages

There are many advantages to adopting the cook-chill method as part of the establishment’s process.

It is suitable for operations of any sizes. In high-volume feeding situations, chain restaurants use it to centralize production and distribute to smaller units. Cook-chill isn’t only for large or multisite operations either. Modest-sized restaurant can make use of cook-chill technology for its banquet and catering needs, or for safe storage of extra portions. It can also be a way to keep a good stock of all menu items on hand at all times by precooking and properly storing them.

It helps with effective time management. Restaurants can organize their kitchen staff’s time for best results, cooking high-volume items when business is slow and having them ready to use when the kitchen is busiest. There can be Labor savings of up to 40% as highly skilled workers can tend to producing the core menu items while relatively unskilled workers can keep up with tasks like portioning and reheating.

Resource management is another advantage. Equipment and space can be used more efficiently and ingredients can be purchased in bulk.

Menu flexibility and diversity. When foods are prepared in advance, some experimentation is possible. Chefs can embellish precooked ingredients to offer a greater overall selection of dishes.

There is also the ability to cater to special dietary needs. For hospitals, senior centers, and schools, nutritional requirements are easier to meet because foods can be pre-portioned and special diet restrictions can be taken into account.

Food also becomes safer as food borne illnesses will be reduced after the food is subjected to the cook-chill process as the whole concept is designed to minimize this critical period.

With the time savings from using the cook-chill system, more time can be dedicated to performing service improvements. The kitchen and waitstaff will have more time to garnish, improve presentation, and attend to customers’ needs.

When food is portioned out into servings, there will be reduced waste, along with improved portion control. This means there will be less food heading for the trash can at the end of the day as it has not been cooked yet and thus no risk of spoilage.

The work atmosphere will be more relaxed, as a result of the reduced cooking and serving time. At the same time, there will be increased profitability since the turnover rate will improve.

How To Buy

When it comes too purchasing a blast chiller, there is more to it than just the size and temperature.

Direct or indirect airflow. Direct airflow is cold air blown directly onto the pans. While it is very effective, there will be more spattering and/or drying out of foods that are not covered. The velocity of the airflow and the way it is balanced are critical considerations. Sufficient air velocity or balanced airflow allows for even chilling of all its contents.

Size. There are two things to be considered. One is the footprint of the appliance and the other is the volume of product that can be chilled per cycle. The specifications should include two measurements of volume: the number of pounds, and the number of pans the chiller can accommodate, per cycle.

Reach-in versus roll-in. Reach-ins are designed to hold a certain number of pans and their shelves may or may not be adjustable. Roll-ins are designed as open cavities into which roll-in racks full of product are wheeled into.

Self-contained versus remote compressor. The compressor in smaller units are self-contained, while larger ones have the option of a separate, stand-alone compressor that requires installation of refrigeration lines between compressor and chiller, more space for the compressor and another electrical connection.

Chilling versus freezing. Some cook-chill systems can also be used as cook-freeze systems. You can buy a blast chiller that has a blast freeze mode and freeze the finished product after quick-chilling.

Last but not least, is the compatibility with other equipment and your product flow.