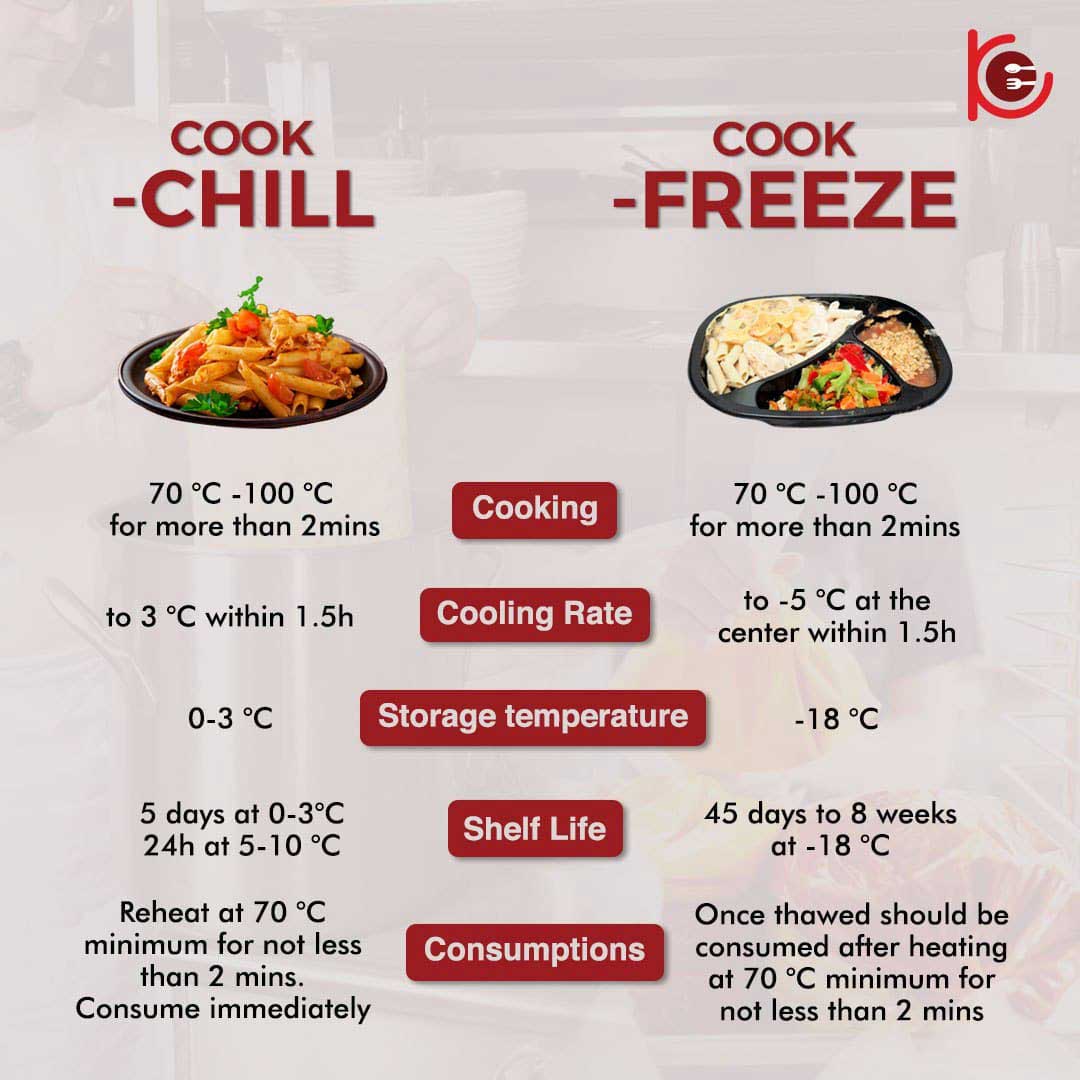

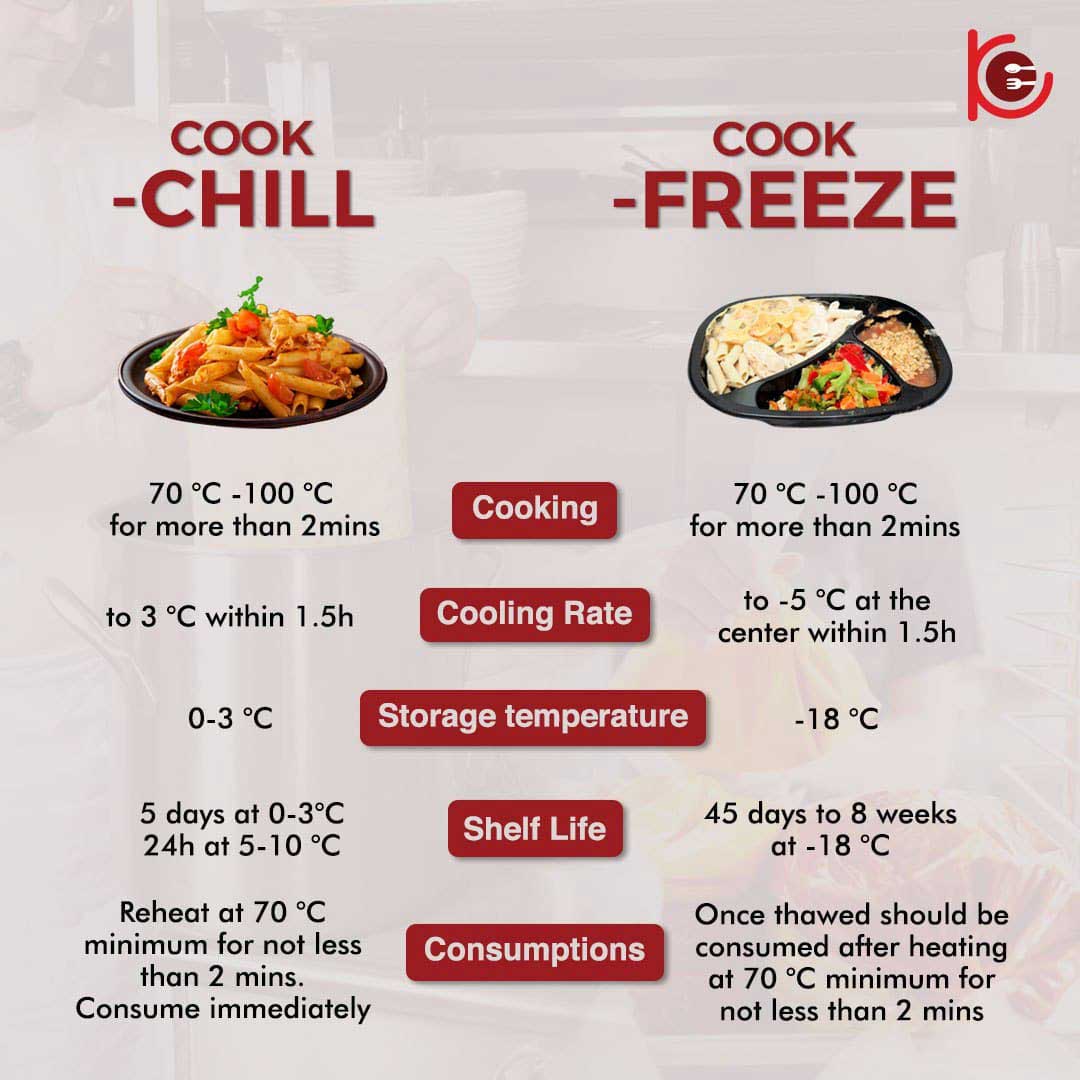

The demand for ready-to-eat fast meals prepared by the food catering sector, outside the home, has increased worldwide. In parallel with this trend, food products from food preparation systems such as cooked-chilled and cooked-frozen foods have increased.

A cook-chill system is a food preservation technology designed to provide more flexibility in foodservice. Food produced using the system retains the taste, texture and aroma of freshly prepared ingredients, yet may have been produced in large volumes up to 8 weeks in advance.

Basically, any food of pumpable consistency can be cooked and prepared at peak quality with the Cook Chill System. This includes soups, chowders, sauces, gravies, gelatins, chili, stews, casseroles, pasta dishes, pizza toppings, and many more. Foods are cooked, packed, quickly chilled, and stored for later use. From large food production kitchens using industrial sized cooking kettles, to single location restaurants, Cook Chill works equally well for any size and need.

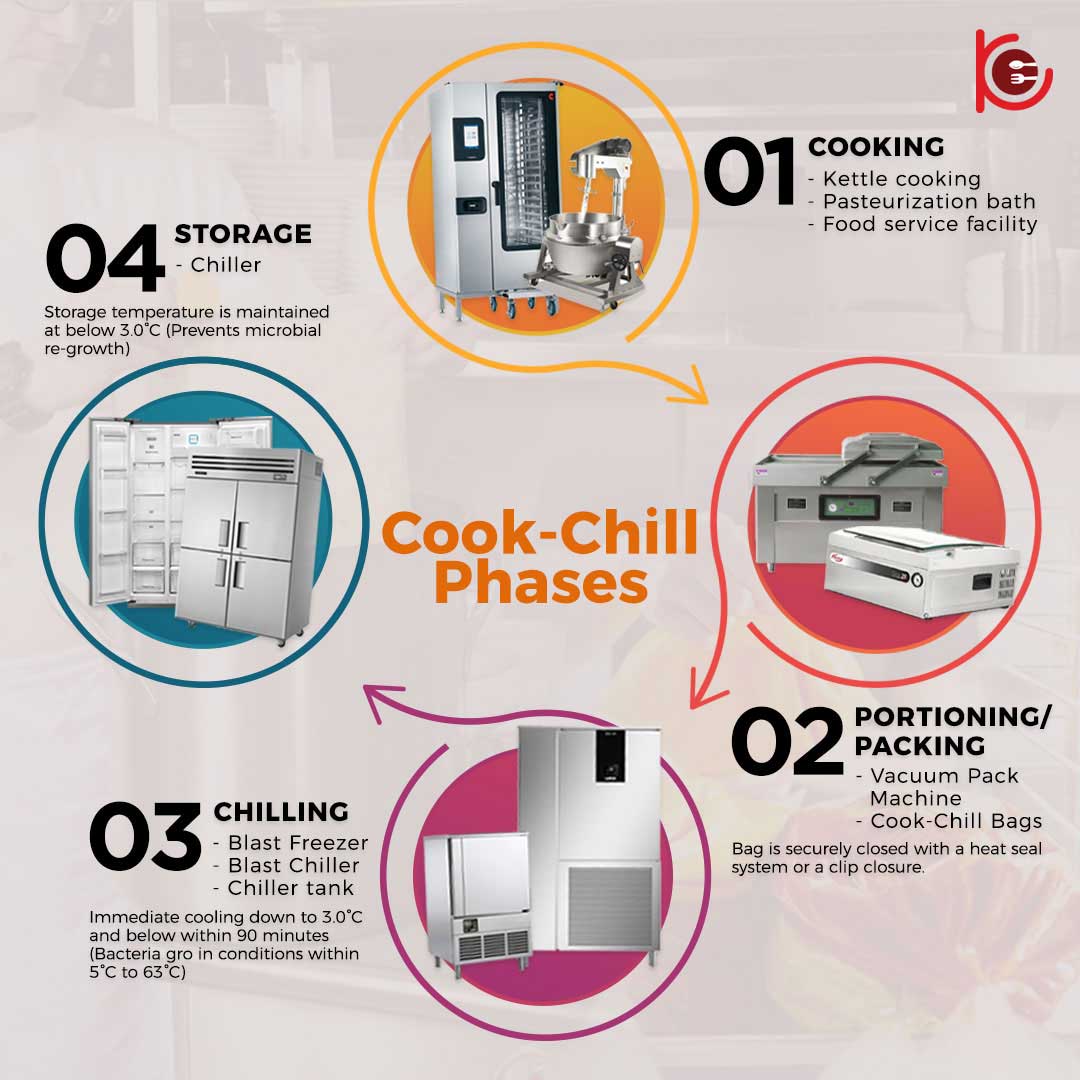

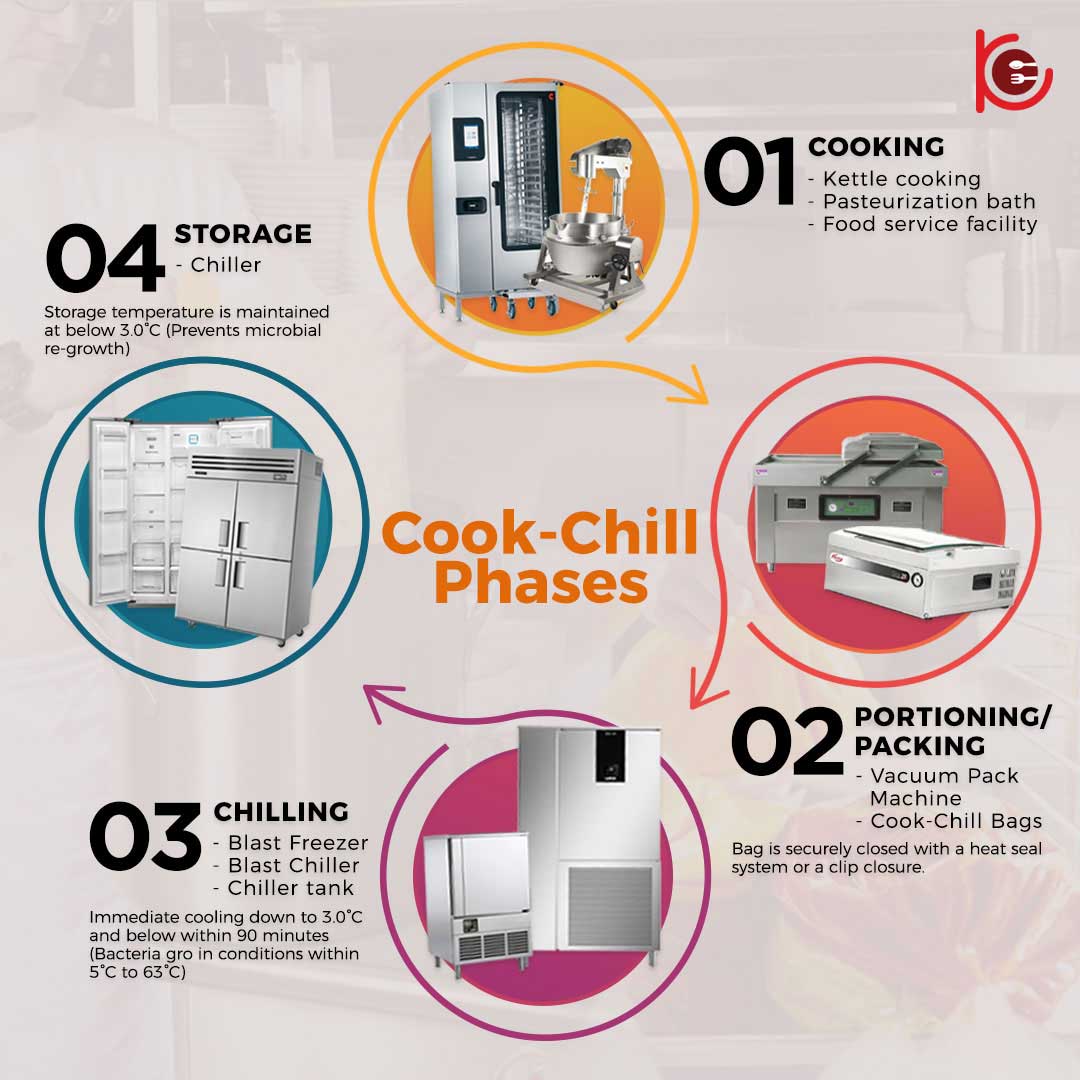

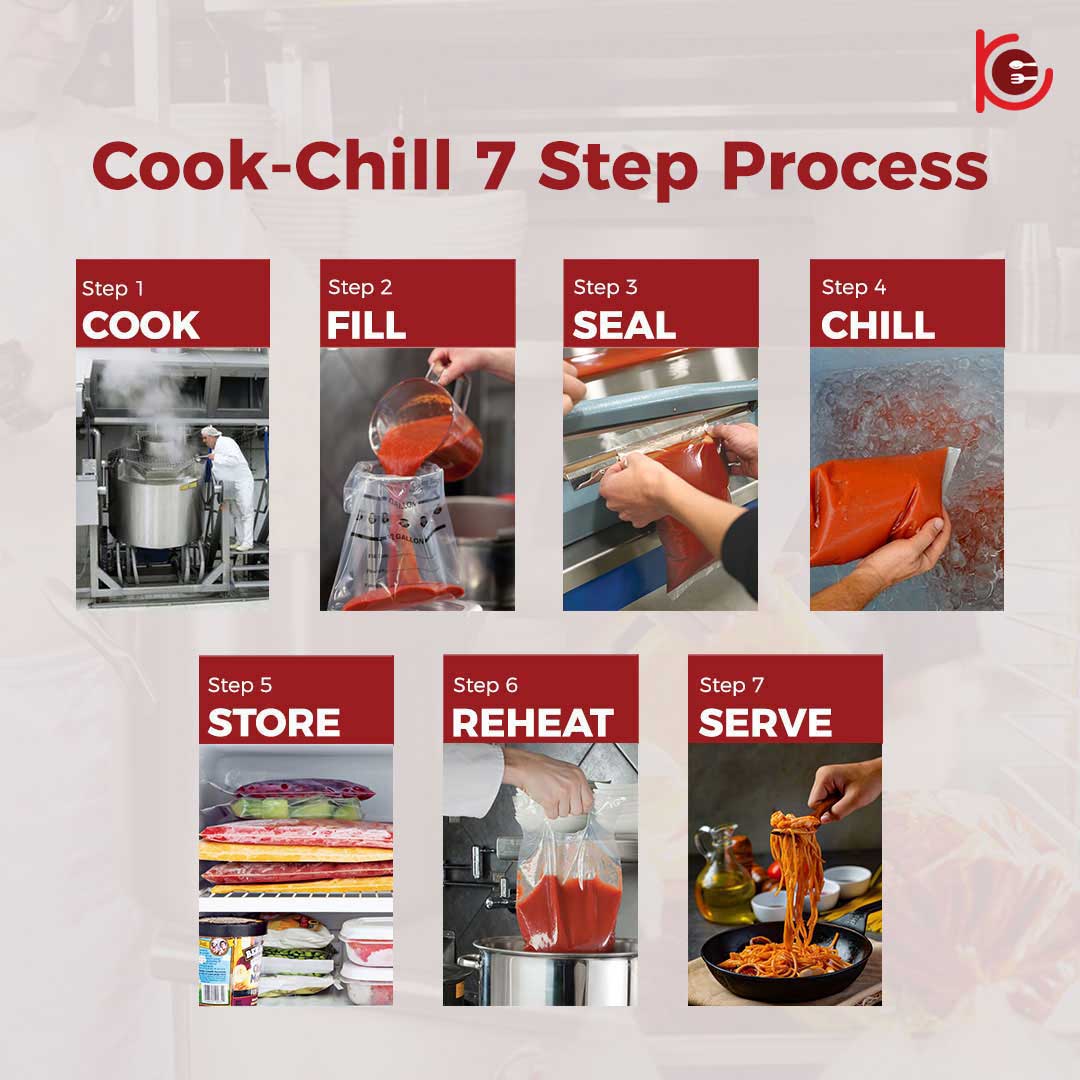

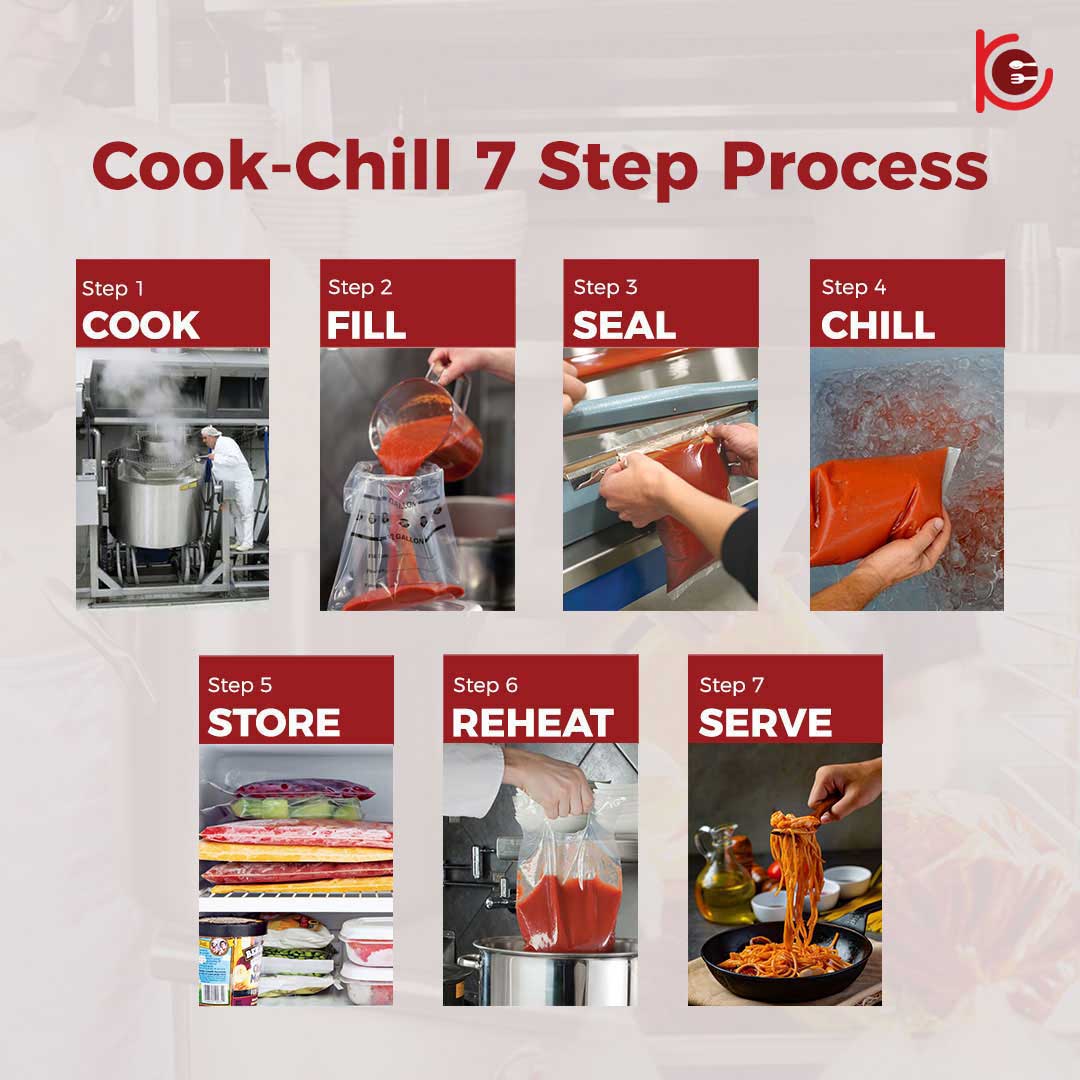

The Cook Chill Prep & Serve Process

It is easiest to view a Cook-Chill system as a series of stages.

Each of these stages should be regarded as equally important to guarantee safety, and good quality dishes.

During food preparation, identification of hazards are categorized into two, which are hazards related to raw materials and hazards related with processes.

In this step, all potential hazards associated with acceptance of raw materials or the receiving of raw materials process were listed. Mise en place of the ingredients includes the unpacking or unboxing process, peeling, thawing, washing, trimming, draining and slicing of ingredients.

Make sure there is good handling of products, food handlers practice good personal hygiene, use of clean utensils and no usage of chemicals during washing of ingredients.

Packaging and labelling must meet requirements too . A cook chill packaging process is one in which cooked foods are placed into oxygen impermeable packaging while still hot and the package is sealed to complete the oxygen barrier .

Sealing to ensure that containers are completely closed, so that nothing can escape or enter the container and contaminate or degrade the food. Labelling All packed and chilled food should be marked with product’s name, date of production, expiry date and to inform kitchen staffs on the reheating instruction.

Meanwhile, to ensure stock rotation means the oldest food stock is used first.

Principal Spoilage Mechanism of Food

Enhancing food shelf life is one way to cater mass food production and this includes food preparation using cook-chill or cook-freeze method . Principal spoilage mechanism of food for ready meals and other cook-chill products is the microbial growth, which is primarily due to post-cooking contamination and/or poor temperature control. By using the HACCP principles, temperature and time monitoring is important to avoid microbial growth .

For instance, thaw frozen meat in a chiller with temperature between 1-10⁰C not exceeding 24 hours to prevent microbial spoilage . Besides, the meat undergoes boiling process to eliminate the microbial hazards..Reheat the meat to a minimum core temperature of 70 ⁰ C for more than 10 minutes prior to consumption.

Meanwhile, rapid chilling is the most effective operational step for preventing microbial growth and toxin production after food is cooked .The time and temperature critical limits parameters were to chill food to core temperature of between 0-3 ⁰C at time between 90 to 120 minutes using blast chiller. Probe thermometer was used to measure the core temperature of food so that it achieves <4 ⁰C.

And to monitor and keep a written account of fridge and freezer temperatures daily. This is done several times each day to ensure the equipment is working properly. The potential microbial growth where it could occur when food is stored for a long time at inappropriate temperature .

In-house preliminary study has shown that the temperature required during storage is 0-3 ⁰C and consumed within 4 days (96 hours), inclusive of the production day. The storage time and temperature is in accordance with past studies related to chilled cooked foods to ensure chilled foods is stored safely for later consumption.