Professional Emission Control meets Flexibility and Efficiency

SMOG HOG® Kitchen emission control systems are customized and can be installed within an existing structure as well as specified with new construction. Additionally, SMOG-HOG® can be programmed into a building maintenance system to operate and self-clean as required by business operations. Smog Hog provides wide selection of configurations and sizes, ranging from 825 – 22000CFM, is ideal for virtually any building design parameter and performance requirement. So regardless of kitchen hood size, Smog Hog emission control systems provide for the ultimate flexibility in location. Smog Hog Kitchen Filter systems can be mounted through exterior walls, on top of buildings, inside mechanical rooms or above the ceiling.

Product Features

- Highest efficiency removal of the widest range of particle size.

- Easily cleaned and reusable ESP collection components eliminates filter replacement and disposal.

- Low energy consumption.

- Less frequent maintenance is required as collected liquid coalesces and drains off aluminium ESP collection components - always Maintains consistent airflow.

- Collection of coils and coolants for reuse Highly effective collection of both oil-and water-based coolants.

- Flexible intake configurations for generals’ area or source capture.

- 22 different mist collection models to accommodate application needs.

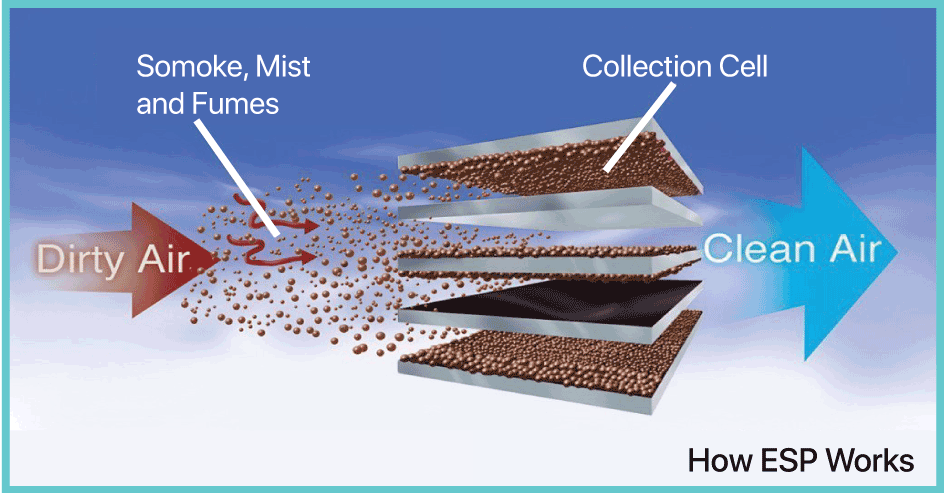

How Smog Hog Works

|

The electrostatic precipitator is usually installed on the inlet (suction) side before the fan. The contaminant-laden air passes through the Pre-filter where coarse particles are removed and optimally distributed in the housing. |

|

The electrostatic field in the ionizer continuously positively charges the remaining fine particulate pollutants in fractions of a second. |

|

The charged particles are then deposited on the Ground/Earthed of the collector, while the cleaned air discharges / exhausts out. The separating plates are designed in such a way that the contaminants run off easily, aiding self-cleaning of the electrostatic precipitator (optional in-place cleaning). |